6

7

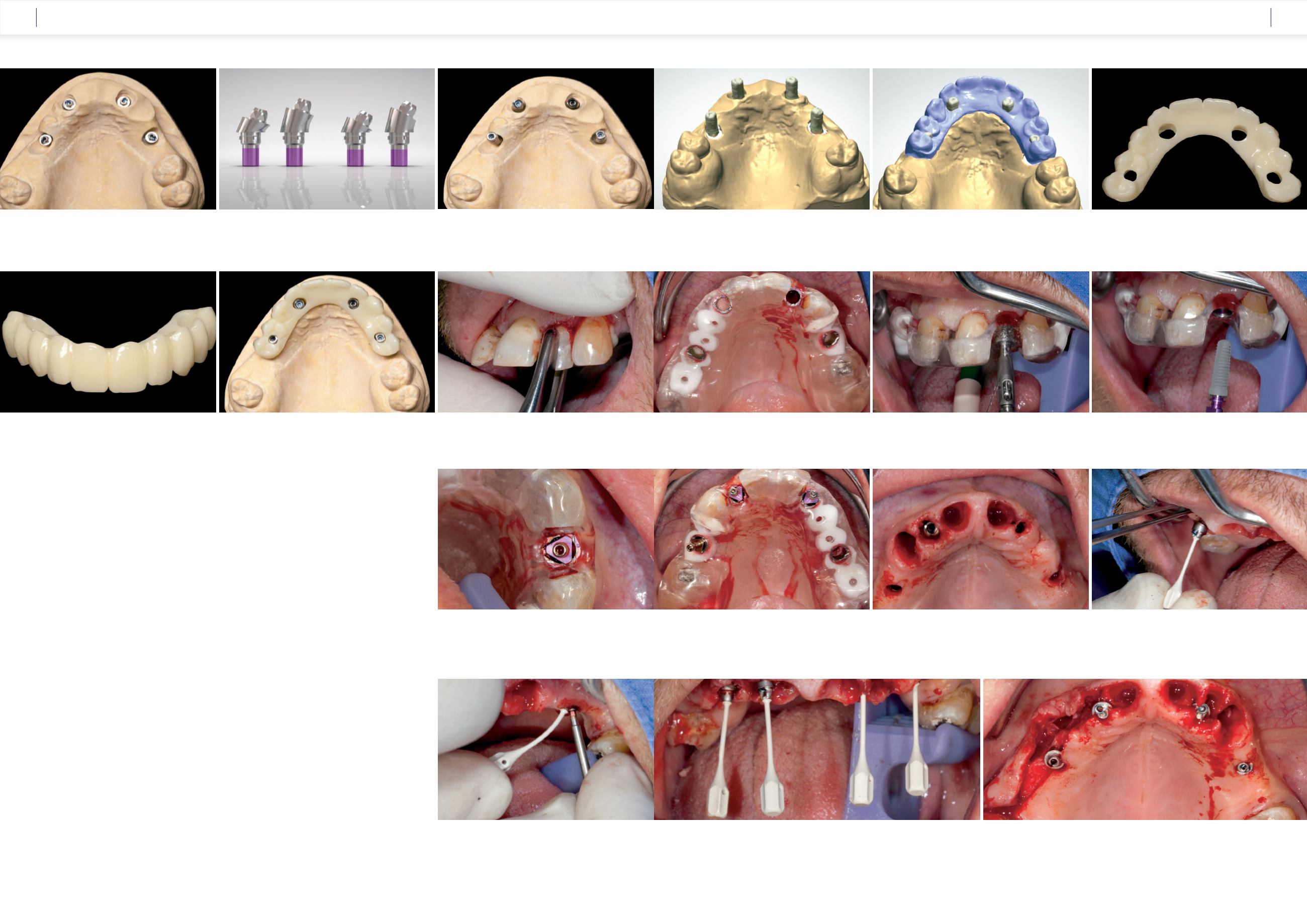

After the titanium caps for bar abutments were

shortened according to the occlusion, we screwed

them on and scanned in the model. The digital

model data were matched with the data from the

setup, the construction was completed digitally,

and the temporary restoration was fabricated in

the CAM procedure using a high-performance

polymer

(Fig. 12 to 16)

. The polymer bridge was

separated from the blank and the fit checked,

ensuring that there is sufficient space around

the titanium caps for the intraoral “adhesion”

(Fig. 17 to 19)

.

The surgical phase

The surgery was carried out under intubation

anesthesia on April 23, 2015. Firstly, we carefully

removed the lateral incisor 22 because this region

was intended for the strategically correct posi-

tioning of an implant based on the Maló princip-

le

(Fig. 20)

. The remaining teeth were used for

precise and stable fixation of the template during

the fully guided insertion of the four CAMLOG

®

Guide SCREW-LINE Implants

(Fig. 21)

. The four

implants (region 12 Ø 4.3 mm CAMLOG

®

SCREW-

LINE Implant 13 mm length, region 22 Ø 4.3 mm/

L 13 mm, region 14 Ø 3.8 mm/L 9 mm and region

25 Ø 3.8 mm/L 13 mm) [6] were inserted using

a minimally invasive procedure according to the

Guide protocol and the inner configuration was

aligned with the marking on the Guide sleeves.

The Guide insertion posts were then screwed on,

the template removed, and the anterior teeth ex-

tracted

(Fig. 22 to 26)

.

The implants were then rinsed, and the

17° angled bar abutments were inserted in

regions 12 and 22. These were supplied pre-

mounted on a flexible insertion handle in sterile

packaging. With the help of this handle,

the abutment is positioned with the precise

angular alignment into the implant

(Fig. 27)

.

To insert the abutment screw, the handle is bent to

one side, giving the surgeon free access to tighten

the screw using the new, slim socket screwdriver

(Fig. 28)

. In the same way, the 30° angled bar

abutments could also be rapidly inserted with pre-

cise alignment and then screwed in

(Fig. 29 and

30)

. We then screwed the titanium caps without

rotation protection onto the COMFOUR

TM

bar

abutments and checked that sufficient space had

been created around the caps to polymerize into

the temporary restoration

(Fig. 31 to 33)

.

Fig. 12:

Two 17° angled COMFOUR™ bar abutments

were used in the anterior region and two 30° angled

bar abutments were used in the dorsal area.

Fig. 14:

The titanium caps were shortened according to the occlusion

and screwed on.

Fig. 15:

The model with the titanium caps screwed on was

scanned …

Fig. 18:

To ensure the hygiene of the restoration, the

basal rest areas and the interdental areas were polished.

Fig. 19:

Checking the fit on the model indicated that the immediate

restoration can be bonded in the mouth without tension.

Fig. 22:

In compliance with the minimally invasive Guide protocol,

the implant bed in region 22 was prepared.

Fig. 23:

The CAMLOG

®

SCREW-LINE implant Ø 4.3 mm/

L 13 mm was inserted through the sleeve to the depth stop.

Fig. 21:

The Guide template was stably fixed over the

remaining teeth.

Fig. 16:

… and matched with the previously scanned setup.

Fig. 17:

The immediate temporary restoration was milled

from high-performance PMMA and the areas around the

titanium caps were generously ground away.

Fig. 20:

Tooth 22 was first carefully extracted.

Fig. 25:

After preparing the implant bed, three implants were

inserted fully guided.

Fig. 29:

The figure shows the approximately parallel alignment of the screw channels of the

prosthetic restoration by means of the angled bar abutments.

Fig. 30:

The flap was formed after a crestal incision with a central band preserved around

the incisive papilla.

Fig. 28:

The abutment screw was tightened using the socket

screwdriver. To gain access, the flexible handle was gently bent to

one side.

Fig. 26:

The periodontally compromised, non-preservable anterior

teeth were extracted after removal of the template.

Fig. 27:

The 17° angled bar abutment was inserted into the

implant with the help of the insertion handle with precise

alignment.

Fig. 24:

The figure shows the precise alignment of the insertion post in

relation to the inner configuration of the implant.

Fig. 13:

COMFOUR™ bar abutments angled at 17° and 30° and with

various gingival heights. They are also available as type B. Not shown:

Straight bar abutment.

CASE STUDY

CASE STUDY