98

|

CAMLOG

®

Product catalog 2017

MATERIALS

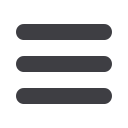

Cast-on gold alloy Base for bar abutment

Properties

Chemical structure (in %)

Au

60

Pt

19

Pd

20

Ir

1

Physical properties

Density

17.5 g/cm

3

Color

white

Liquidus

1490 °C

Solidus

1400 °C

Coefficient of

thermal expansion

(25-500°C)

12.5 μm/m

·

°C

Coefficient of

thermal expansion

(25-600°C)

12.6 μm/m

·

°C

E-Modul

136 GPa

Mechanical properties

hardened

700 °C/30 min.

Hardness HV5

210

0.2 % Elongation

limit

450 – 570 MPa

Elongation at

break

min. 10 %

Tensile strength MPa

530 – 650

Titanium Grade 4

Properties (ASTM F67)

Chemical structure (in %)

O ≤ 0.4

Fe ≤ 0.5

C ≤ 0.08

N ≤ 0.05

H ≤ 0.015

Ti

Rest

Mechanical properties

Tensile strength ≥ 550 MPa

Elongation at

break

≥ 12 %

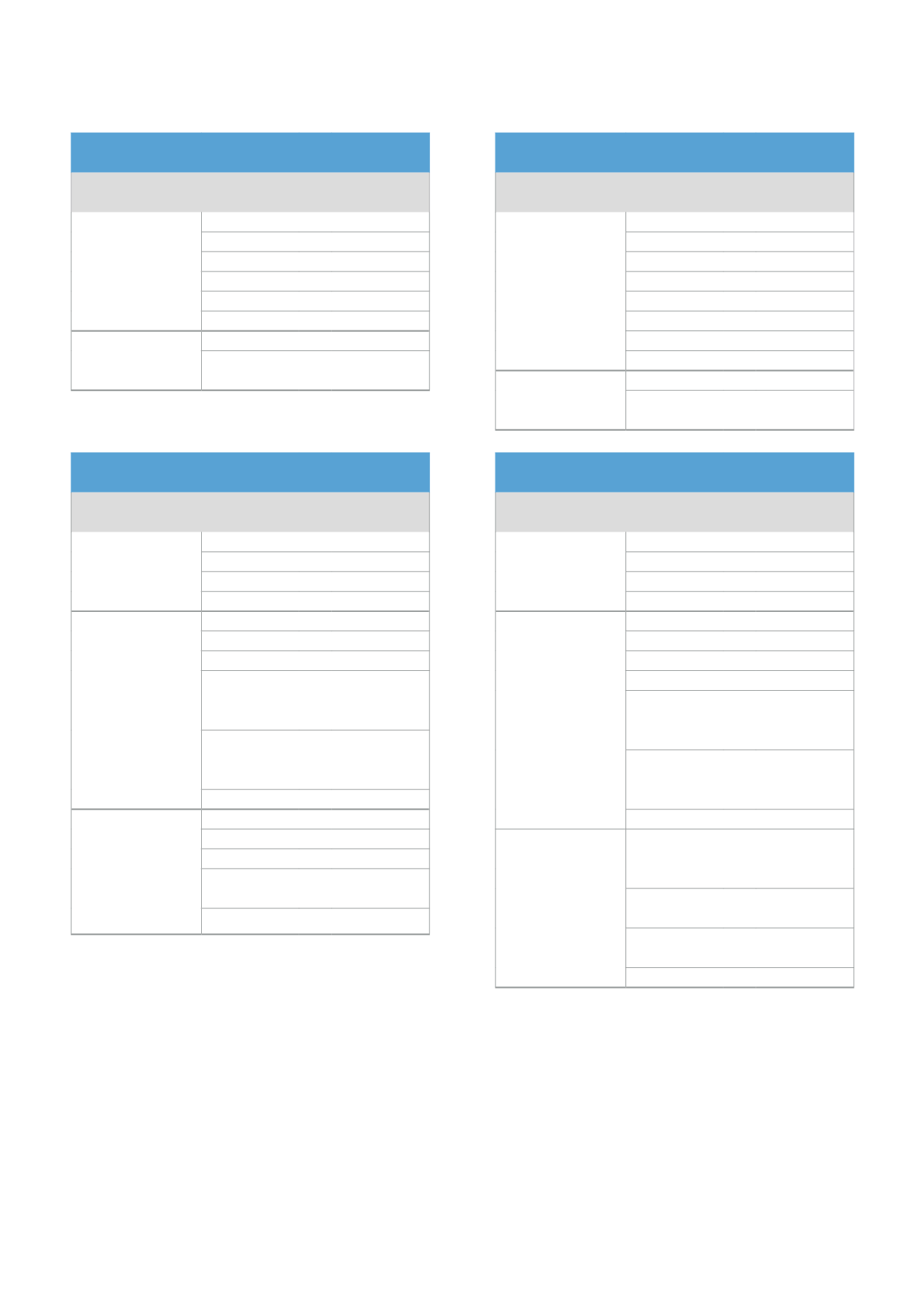

Cast-on gold alloy CAMLOG

®

Gold-plastic abutment

Properties

Chemical structure (in %)

Au

60

Pd

20

Pt

19

Ir

1

Physical properties

Melting range

1400 – 1490 °C

Density

17.5 g/cm

3

E-Modul

136 GPa

Coefficient of

thermal expansion

(25-500°C)

11.9 μm/m

·

°C

Coefficient of

thermal expansion

(25-600°C)

12.2 μm/m

·

°C

Color

white

Mechanical properties

drawn

Hardness HV5 > 215

Tensile strength (Rm) > 750 MPa

0.2% Elongation

limit (Rp 0.2%)

> 650 MPa

Elongation at break > 2 %

Titanium alloy Ti6AI4V ELI

Properties (ASTM F136)

Chemical structure (in %)

AI

5.5 – 6.5

V

3.5 – 4.5

Fe ≤ 0.25

C ≤ 0.08

N ≤ 0.05

O ≤ 0.13

H ≤ 0.012

Ti

Rest

Mechanical properties

Tensile strength ≥ 860 MPa

Elongation at

break

≥ 10 %