4

|

CONELOG

®

Product catalog 2017

ADVANTAGES AND BENEFITS – IMPLANT-ABUTMENT CONNECTION

• High level of user safety thanks to the connection design

• High positioning accuracy

• Self-locking connection through conical geometry

• No complicated transfer key for abutments required

• Time savings due to quick and easy positioning of the abutments

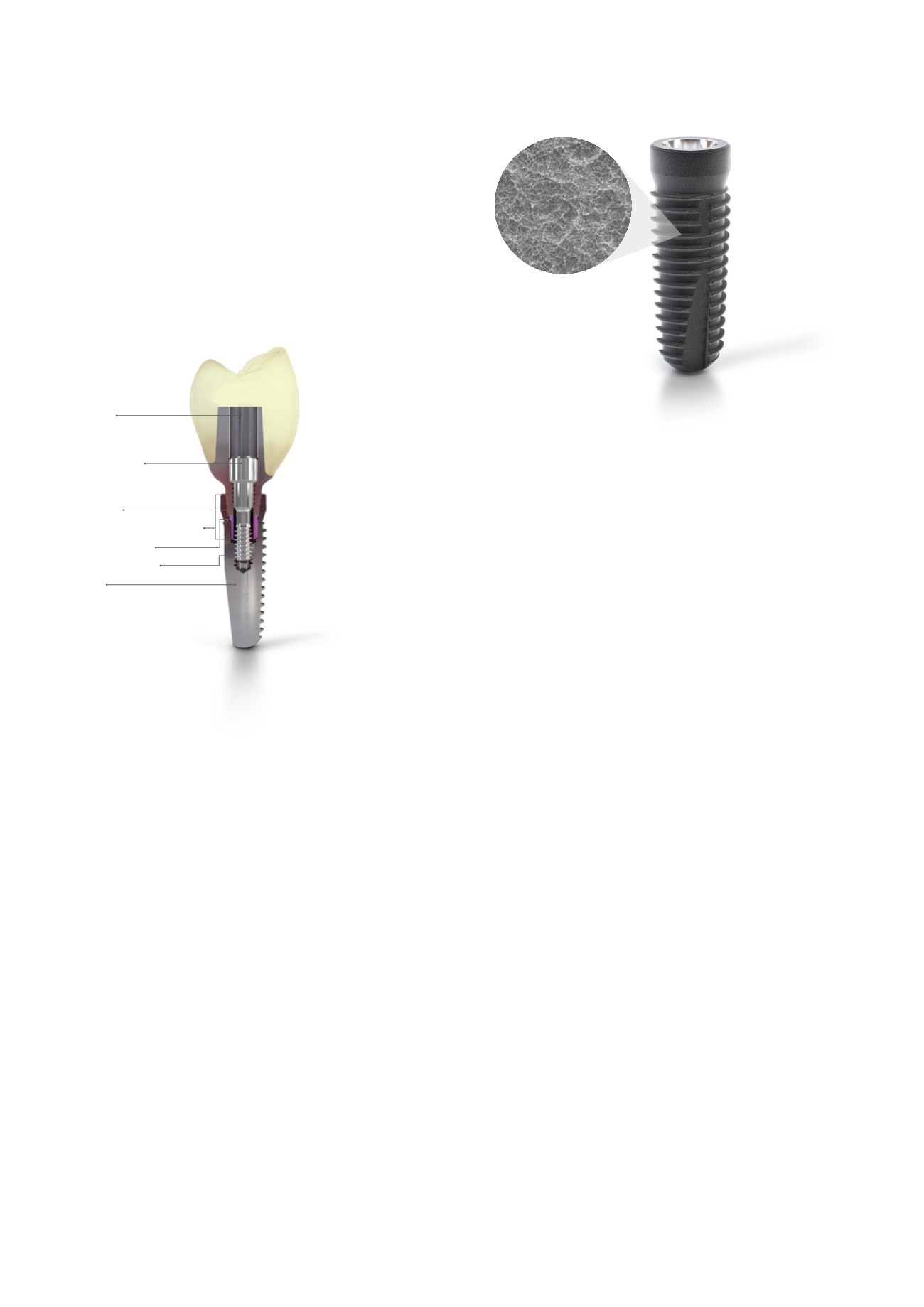

PROMOTE

®

SURFACE

CONELOG

®

Implants are available with the abrasive-blasted,

acid-etched Promote

®

surface which extends over the entire

implant body up to the acid-etched conical 45° implant shoulder.

The surface is based on current scientific knowledge and supports

rapid osseointegration. Scientific results from studies with cell

cultures, osteohistology and in pull-out trials illustrate this

impressively.

CONELOG

®

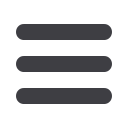

SCREW-LINE IMPLANT ABUTMENT CONNECTION

A 7.5° internal cone provides reliable transfer of force/torque and is fitted

with the three proven grooves for precision abutment positioning. Clearly

perceptible tactile feedback indicates when the abutment is positioned

correctly by the three cams and apical cone.

The CONELOG

®

Abutments are fitted apically with a cone and three cams

and lock into the conical connection and the three grooves of the implant.

The CONELOG

®

Abutment does not cover the implant shoulder, thus allowing

Platform Switching. For optimal positioning of the abutments, the implant

should be aligned in the bone so that one of the three grooves points in

vestibular direction. With the CONELOG

®

SCREW-LINE implants, the insertion

tools include markings that correspond to the three grooves of the implant‘s

inner configuration.

Abutment

Abutment screw

Conical implant-abutment

connection

Abutment guide in the implant

Groove/cam design

Implant inner thread

Implant