5

THE CAMLOG

®

IMPLANT SYSTEM

SYSTEM INFORMATION

CAMLOG

®

IMPLANTATSYSTEM

CAMLOG SURFACE STRUCTURES

Promote

®

surface

CAMLOG

®

Implants are available with the Promote

®

surface.

On CAMLOG

®

SCREW-LINE Implants, the abrasive-blasted,

acid-etched Promote

®

surface extends up to 1.4 mm under

the implant shoulder and the Promote

®

plus surface up to

0.4 mm under the implant shoulder. In the case of CAMLOG

®

ROOT-LINE 2 Implants this reaches up to 0.4 mm under the

implant shoulder (Promote

®

plus). The Promote

®

surface

has proven its worth as a surface for anchoring dental

implants in the bone and has shown good scientific results

in osteohistology and in pull-out trials. These results suggest

that the Promote

®

surface leads to rapid osseointegration of

the CAMLOG

®

Implants.

Promote

®

surface

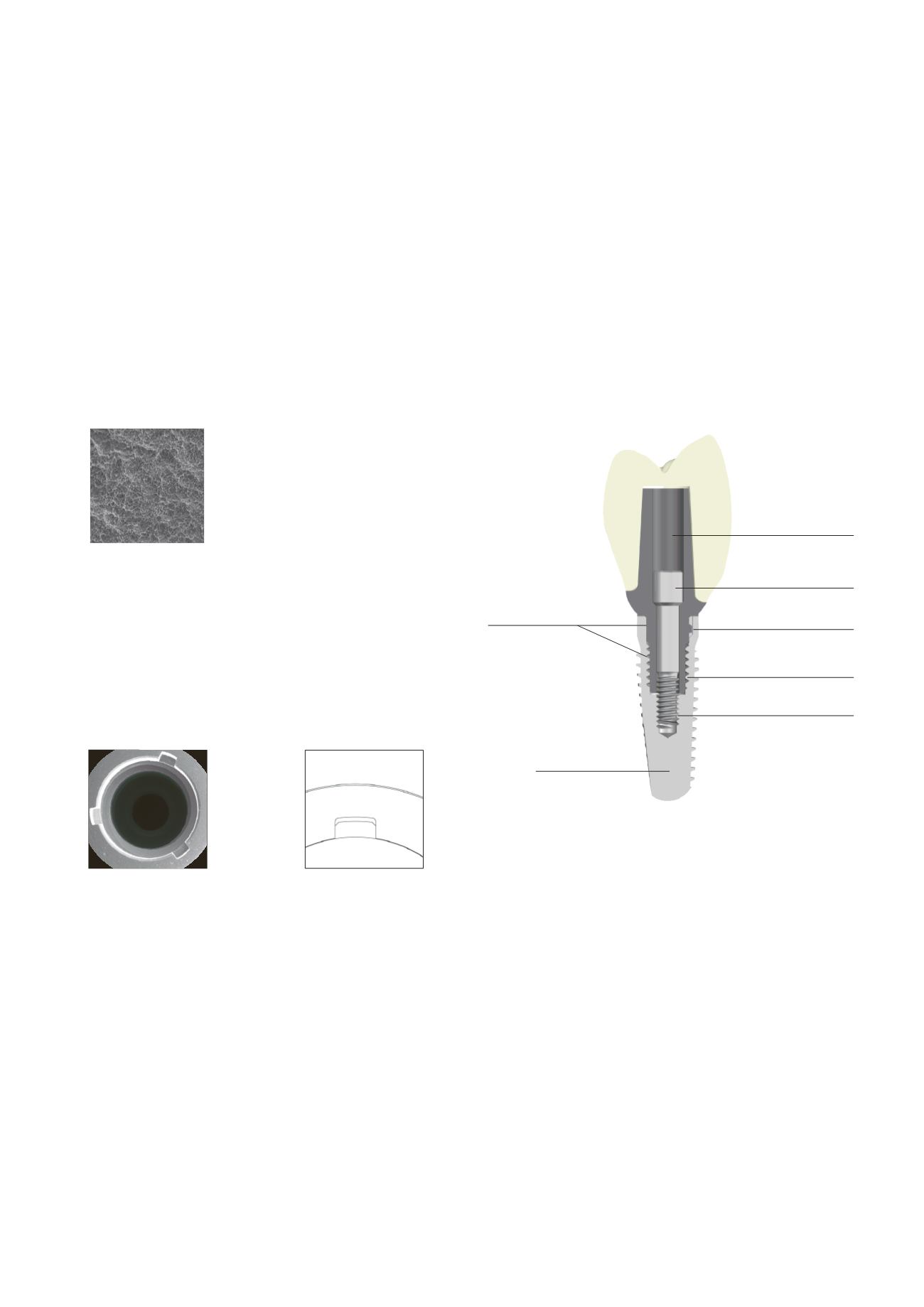

CAMLOG

®

Tube-in-Tube™ Implant-Abutment

Connection

All CAMLOG

®

Implants are equipped with the proven Tube-

in-Tube™ implant-abutment connection and feature three

symmetrically arranged angular grooves (width 0.5 or

0.7 mm, depth 1.2 mm).

CAMLOG

®

Implant inner thread and outer geometry

Within the Tube-in-Tube™ Connection, an upper inner

thread attaches for all CAMLOG

®

Implant lines with

3.8/4.3/5.0/6.0 mm outer diameter, in which the thread of

the CAMLOG

®

Healing cap engages (for CAMLOG

®

Implants

with

Ø

3.3 mm lower inner thread only). There is a second

inner thread towards the apex M 1.6 or M 2.0 (to receive the

CAMLOG

®

Abutment and fixing screw).

For optimal positioning of the abutments in the implant,

they should be aligned in the bone so that one of the three

grooves points vestibularly. With the CAMLOG

®

SCREW-LINE

and ROOT-LINE 2 Implants, the drivers include markings

that correspond to the three grooves of the implant inner

configuration.

The inner and outer geometry of the CAMLOG

®

Implants and

abutments are rotary machined for the most part. The toler

ances can therefore be kept very low. The result is excellent

part precision without impacting the material structure. The

patented Tube-in-Tube™ Design of the implant abutment

connection (Patent EP 851 744 and corresponding proper-

ty rights) thus ensures a very precise, stable and rotation-securing connection to the prosthetic components.

CAMLOG

®

Abutment

CAMLOG

®

Abutment screw

CAMLOG

®

Groove/cam design

Upper inner thread

Lower inner thread

Abutment guide

in the implant

CAMLOG

®

Implant