CAMLOG

®

Implant Position Planning

PRODUCTION PRECISION

The inner and outer geometry of the implants and abutments are rotary ma-

chined for the most part. The production tolerances can therefore be very

tightly maintained. The result is a precise and accurate fit of components

without compromising the material structure. The patented Tube-in-Tube™

design of the implant abutment connection (Patent EP 851 744 and corre-

sponding property rights) ensures a very precise, stable and rotation-secur-

ing connection to the prosthetic components.

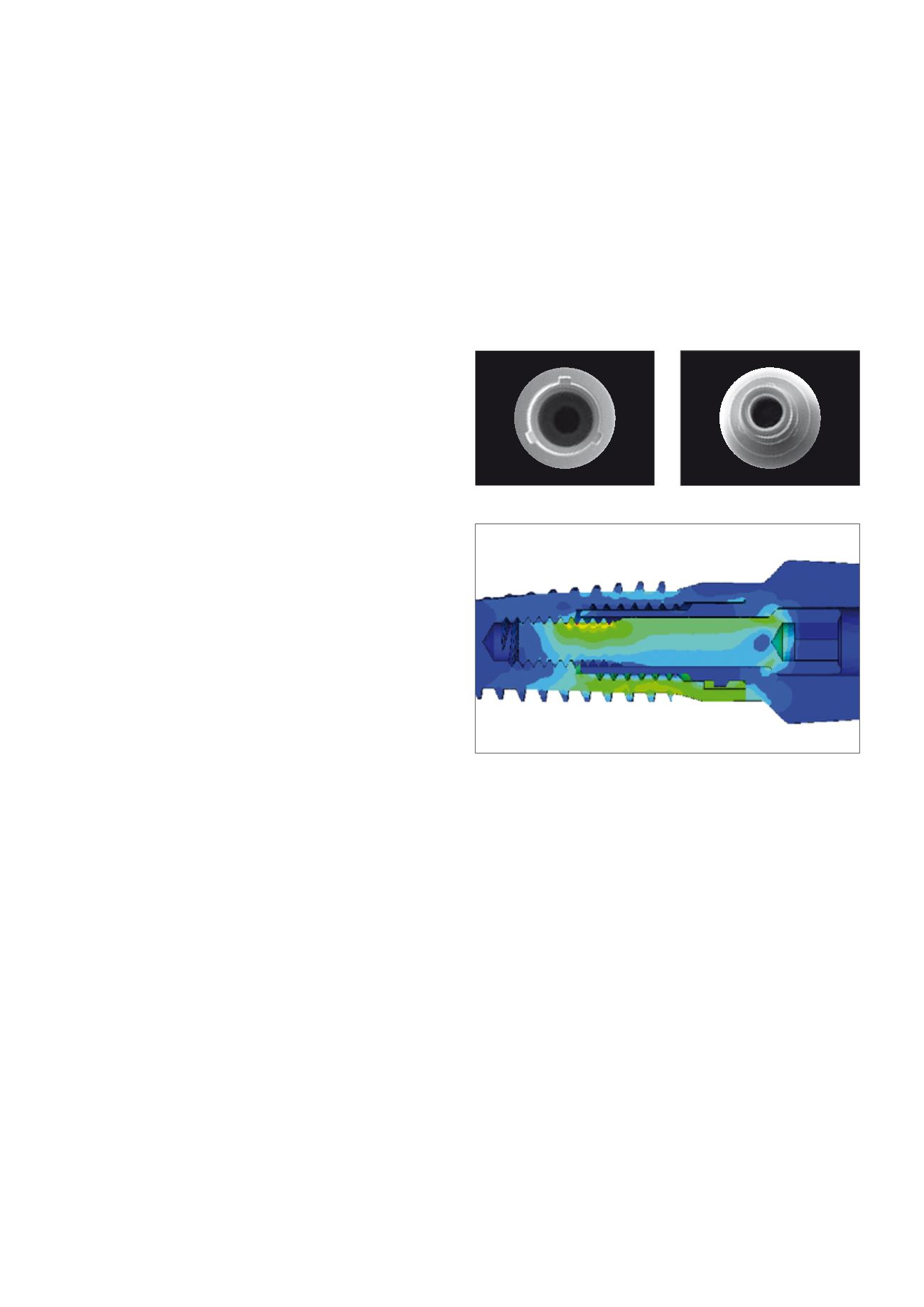

SHORT CAM GEOMETRY CONNECTION (K-SERIES)

The implant abutment connection for the CAMLOG

®

Implant System is pre-

dominantly a form-fit connection. The connection with the short cam ge-

ometry has been optimized biomechanically by means of extensive finite

element analyses. The figure to the right shows the distribution of the von

Mises stress in the implant abutment connection at a load in accordance to

ISO 14801 with 200 N.

MATERIALS

All CAMLOG

®

implants are made from pure grade 4 titanium, the abut-

ments and abutment screws from titanium alloy Ti6Al4V (ASTM F136).

SCREW-LINE Implant (K-Series)

von Mises stress

Abutment (K-Series)