CAMLOG

®

Implant Position Planning

PROMOTE

®

SURFACE

TITANIUM PLASMA

COATING (TPS)

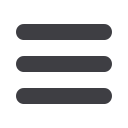

The SCREW-LINE, ROOT-LINE and SCREW-

CYLINDER-LINE implants are available with the

sandblasted, acid-etched Promote

®

surface. The

microstructured, rough surface for SCREW-LINE

implants with Promote

®

surface extends in the

endosseous area apically up to 1.4 mm below

the implant shoulder and for ROOT-LINE and

SCREW-CYLINDER-LINE implants with Promote

®

surface up to 2.0 mm below the implant shoulder.

For SCREW-LINE implants with Promote

®

plus

surface, the rough/smooth boundary is up to

0.4 mm below the implant shoulder. Promote

®

has proven itself as the surface for anchoring

CAMLOG

®

implants in the bone. Scientific stud-

ies show that implants with Promote

®

surface

rapidly and efficiently integrate into the bone

(Schwarz et al., 2008; Nelson et al., 2008; Sem-

per et al., 2008).

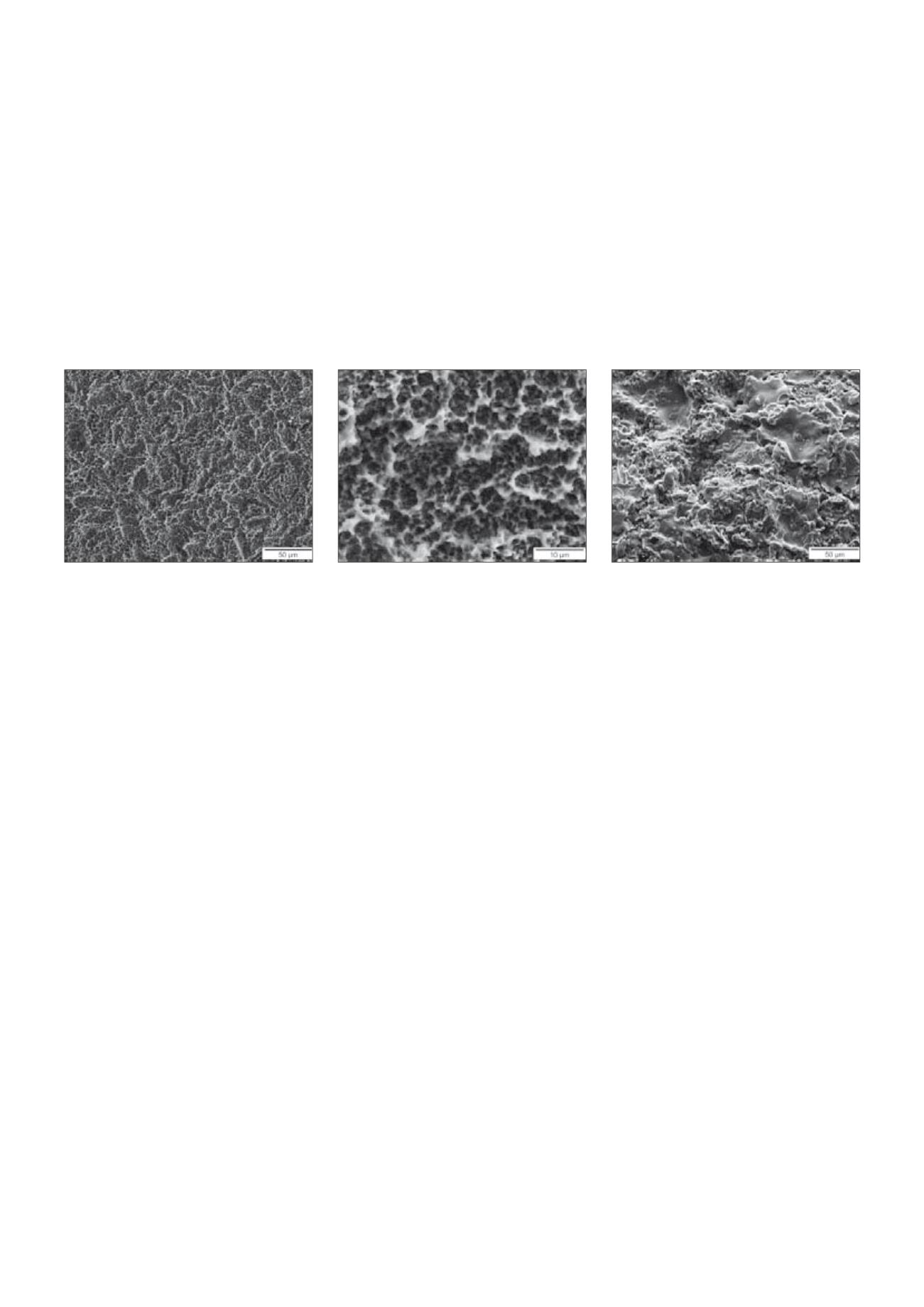

CYLINDER-LINE implants have a titanium plasma

coating in the endosseous area up to 2.0 mm be-

low the implant shoulder. The reliability of this

surface is very well documented by years of suc-

cessful use.

REFERENCES

Schwarz F., Herten M., Bieling K., Becker J.

Crestal bone changes at nonsubmerged implants (Camlog)

with different machined collar lengths:

a histomorphometric pilot study in dogs. Int J Oral

Maxillofac Implants 2008;23:335–342

Nelson K., Semper W., Hildebrand D., Özyuvaci H.

A retrospective analysis of sandblasted, acid-etched

implants with reduced healing times with an observation

period up to 5 years. Int J Oral Maxillofac Implants

2008;23:726–732

Semper W., Heberer S., Nelson K.

Early loading of root form and conical implants with a

sandblasted large-grit acid-etched surface: a 6-year clinical

follow-up. Implants 2008;2:14–19

Scanning electron micrograph of the

Promote

®

surface (1000x magnification)

Scanning electron micrograph of the

Promote

®

surface (5000x magnification)

Scanning electron micrograph of the titanium plasma

coated surface TPS (1000x magnification)

CAMLOG

SURFACE STRUCTURES