CAMLOG&Science – Chapter 1

4 | 5

The CONELOG

®

(patent pending)

connection con-

sists of a coronal

1.5 to 1.9mm long,

self-locking 7.5° taper for reliable

transfer of forces and torques fol-

lowed by a short cylindrical seg-

ment with three symmetrically

arranged grooves. The grooves

of the implant fit perfectly in the

corresponding cams of the abut-

ment enabling precise abutment

positioning.

CONELOG

®

Implant System

CAMLOG

®

Implant System

Implant system

Geometry

Implant

Machined surface at

implant neck

Surgical drill sequence

Platform switching

Implant-abutment

connection

Prosthetics

Rough enossal surface

CAMLOG

®

SCREW-LINE AND CONELOG

®

SCREW-LINE IMPLANTS: SIMILARITIES AND DIFFERENCES

CAMLOG

®

SCREW-LINE

Promote

®

1.4 mm

Conical, threaded screw with cylindrical neck

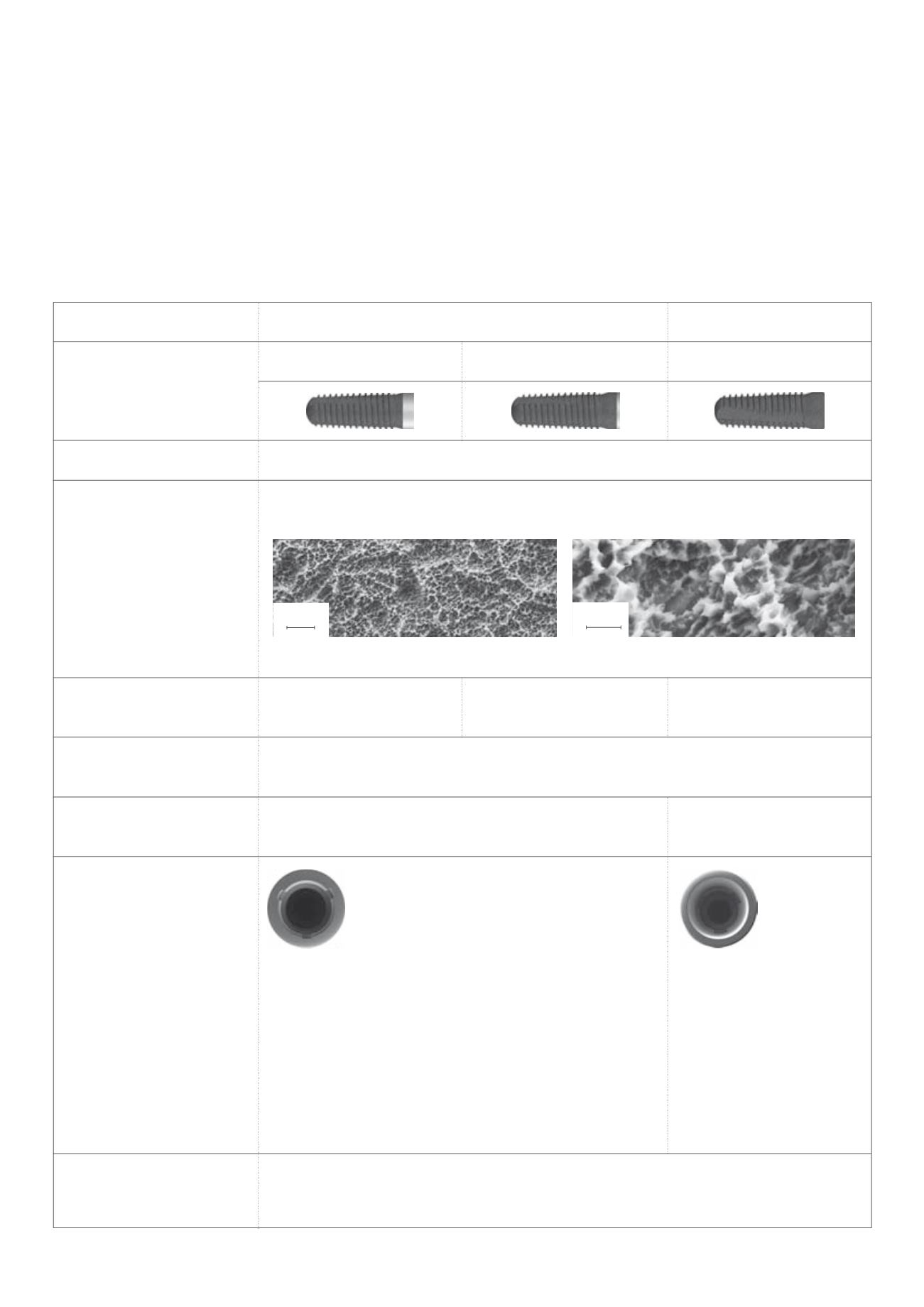

The state-of-the-art, sand-blasted, acid-etched Promote

®

surface favors rapid and stable osseointegration.

Evidence for this derives from cell culture experiments, animal studies and clinical trials.

Different magnifications of scanning electron microscopy pictures of the Promote

®

surface

Due to the identical geometry of all three implant types, one surgical kit and an identical surgical drill sequence

can be used.

Platform-switched or non-platform-switched restoration possible

The Tube-in-Tube™ (patented) connection contains co-

ronal a 1.9 mm long cylindrical tube with three symme-

trically arranged grooves followed by a smaller cylindri-

cal longer tube. When inserting the abutments, their

tubular extension towards the apex affects the simple,

easy and safe orientation in the longitudinal axis of the implant before

the three cams lock into the grooves of the implant. By rotation, the

correct abutment position is easy to find.

The CAMLOG

®

Tube-in-Tube™ connection was subject of intensive

research and comparative studies with other well-known implant sys-

tems demonstrating above average results for fitting accuracy and

leakage prevention for the Tube-in-Tube™ connection.

Only platform-switched

restoration possible

CAMLOG

®

SCREW-LINE

Promote

®

plus

0.4 mm

CONELOG

®

SCREW-LINE

Promote

®

plus

no

Tab. 1:

Similarities and differences of the CAMLOG

®

and CONELOG

®

Implant Systems

20μm

5μm

Small prosthetic units, CAD/CAM based restorations, intraoral bonding to obtain passive fit, passive fit bar

technology, and high-precision adaptation of the secondary parts for electroplated telescopic crowns are all

standard with the CAMLOG

®

and CONELOG

®

Implant Systems.