CAMLOG&Science – Chapter 2

6 | 7

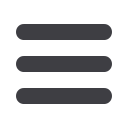

Fig. 4A:

Abutments were removed from the titanium/patient model seven times and refastened

with 10 Ncm, 20 Ncm and 30 Ncm torques to the same model in order to analyze system-inherent

inexactness resulting from the abutment/implant fastening method. (Reinert and Geis-Gerstorfer

2007, reproduced with kind permission of Deutscher Ärzte-Verlag).

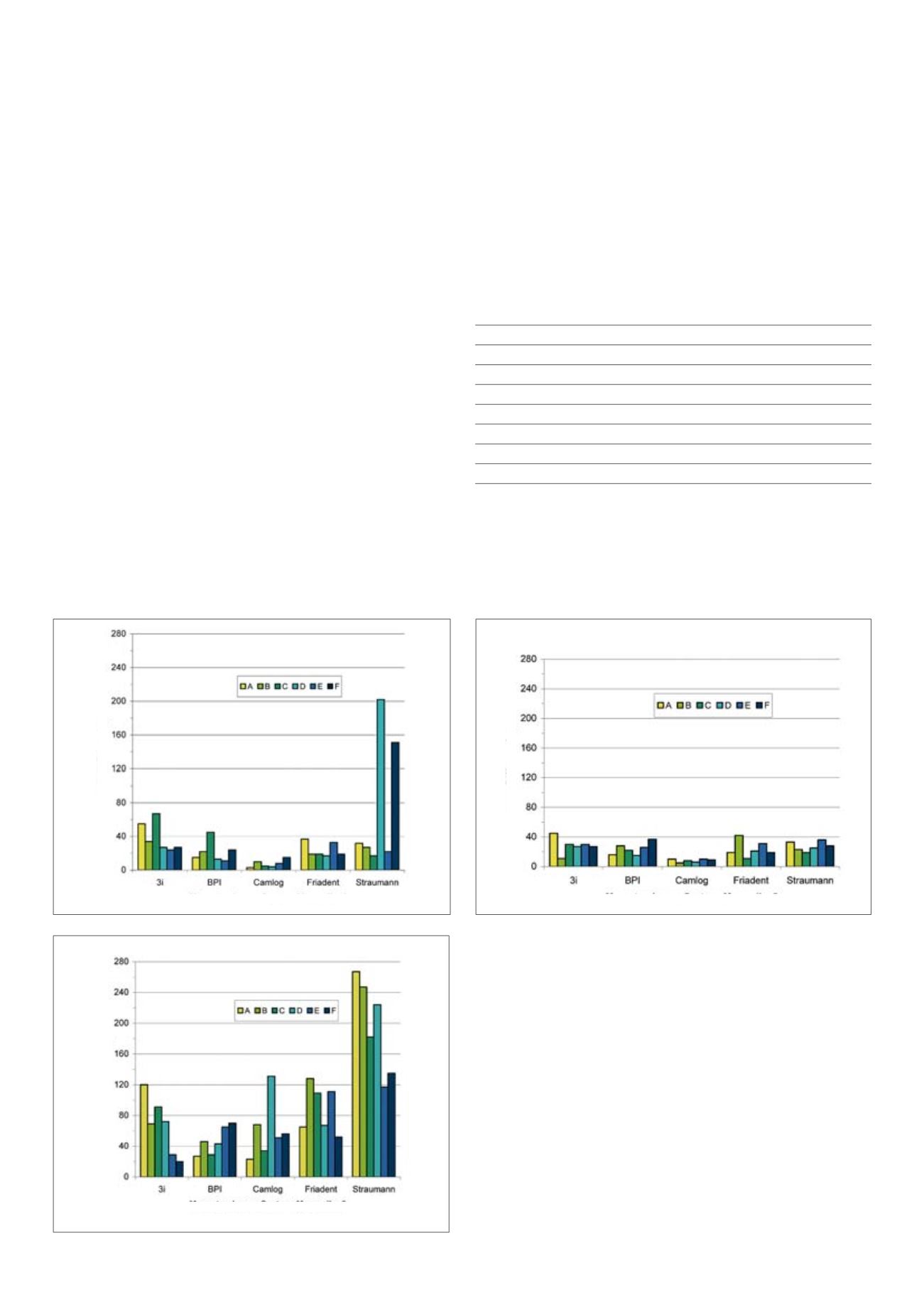

Fig. 4B:

Defects resulting from the transfer method used with open impressions were evaluated

by measuring six plaster casts obtained from the same titanium model. The effect of the impres-

sion material and plaster on precision is evident. (Reinert and Geis-Gerstorfer 2007, reproduced

with kind permission of Deutscher Ärzte-Verlag).

Fig. 4C:

Defects in precision and stability or resistance in the lab analogues during the fabrication

process for superstructures in the laboratory were evaluated by removing all abutments from one

of the six produced plaster casts seven times and by refastening them with torques of 10 Ncm, 20

Ncm and 30 Ncm to the same model. (Reinert and Geis-Gerstorfer 2007, reproduced with kind

permission of Deutscher Ärzte-Verlag).

3i

BPI

CAMLOG Friadent

Straumann

Re-attachment of abutments to titanium model

39.0 μm

21.7 μm

7.5 μm

24.0 μm

75.2 μm

Precision of entire system

66.8 μm

46.7 μm

60.5 μm

88.7 μm

195.3 μm

Re-attachment of the abutments to plaster cast

28.3 μm

24.0 μm

8.0 μm

23.8 μm

27.3 μm

Tab. 2:

Mean measured values of the measuring series. (Adapted from Reinert and Geis-

Gerstorfer (2007)).

Three measuring series were performed, and the results are shown in Figures

4A–4C and Table 2. Each column stands for the measured values of a measured

section. In measuring series 1, the CAMLOG

®

Implant System was conspicuous;

its mean measuring variance lay within the measuring precision of the

measuring device established in pretests. Measuring series 2 showed the

greatest measuring variance since here the impression material and the

plaster were added as sources of defects. The researchers believed that the

impression post design is of decisive importance. Here, the BPI system

appeared to offer benefits. In measuring series 3, the CAMLOG

®

Implant

System again was superior and showed the least measuring variance.

The authors concluded that the precision of fit of a superstructure on an implant

may not only be determined by the dental laboratory fabrication process, but

alsoby the system itself throughan inadequatefit of theabutment onthe implant.

max. variance in μm

Measuring range per system, measuring series 1

A

max. variance in μm

Measuring range per system, measuring series 3

C

B

max. variance in μm

Measuring range per system, measuring series 2