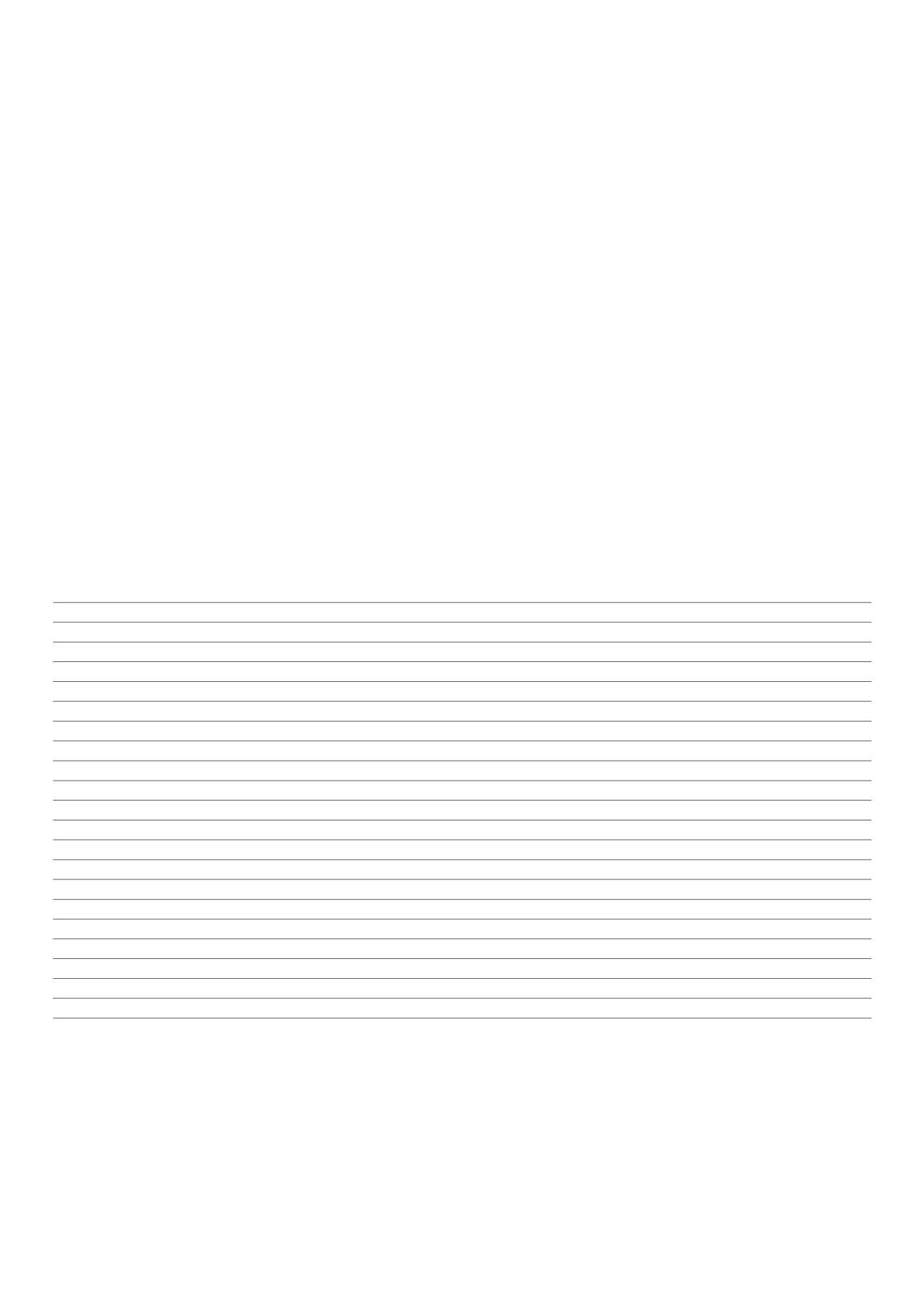

CAMLOG&Science – Chapter 2

With the help of a three-dimensional computer simulation, the same group

evaluated clinical relevance of the rotational freedom of angulated abut-

ments on the marginal fit of the prosthetic superstructures (Semper et al.,

2010a). The horizontal displacement of virtually constructed idealized

abutments with different angulations (range from 0 to 20°) was simulated

with various degrees of rotational freedom (range from 0.7 to 1.85°) previ-

ously described (Semper et al., 2009b). After quantification of the resulting

displacement, a subsequent simulation was performed where the super-

structure with different defined internal gaps (5 μm, 60 μm and 100 μm)

was positioned pressure-less on the displaced abutments. Finally, the resul-

ting marginal gap between the abutment and the superstructure was mea-

sured with the software (Tab. 3).

Tab. 3:

The size of the marginal fit gap of the superstructures depends on the degree of abutment

angulation and rotational freedom ranging from 17 μm to 2.33 mm maximum when the internal

precision of the superstructure was 5 μm. A range from 18 μm to 802 μm was observed with an

internal precision of 60 μm, and from 19 μm to 162 μm with 100 μm. Based on this investigation

the authors concluded that the rotation of the abutment is of clinical relevance because of its im-

pact on the marginal fit of the prosthetic superstructure. (Adapted from Semper et al. (2010a)).

MARGINAL FIT OF THE SUPERSTRUCTURE AT DIFFERENT ASSUMED INTERNAL PRECISIONS SIMULATED WITH DIFFERENT DEGREES OF

ROTATIONAL FREEDOM AND ABUTMENT ANGULATIONS

Internal gap /

Rotational freedom (

_

/2)

abutment angulation

angulation

0.7 deg

0.95 deg

1.5 deg

1.65 deg

1.85 deg

5 μm assumed internal precision

0 deg

17 μm

40 μm

183 μm

203 μm

266 μm

5 deg

187 μm

316 μm

578 μm

633 μm

782 μm

10 deg

401 μm

597 μm

1.03 mm

1.17 mm

1.31 mm

15 deg

597 μm

868 μm

1.47 mm

1.66 mm

1.87 mm

20 deg

796 μm

1.11 mm

1.82 mm

2.05 mm

2.33 mm

60 μm assumed internal precision

0 deg

18 μm

23 μm

33 μm

43 μm

45 μm

5 deg

18 μm

23 μm

33 μm

43 μm

45 μm

10 deg

18 μm

23 μm

33 μm

43 μm

45 μm

15 deg

18 μm

23 μm

33 μm

89 μm

316 μm

20 deg

18 μm

23 μm

33 μm

576 μm

802 μm

100 μm assumed internal precision

0 deg

19 μm

25 μm

37 μm

44 μm

50 μm

5 deg

19 μm

25 μm

37 μm

44 μm

50 μm

10 deg

19 μm

25 μm

37 μm

44 μm

50 μm

15 deg

19 μm

25 μm

37 μm

44 μm

50 μm

20 deg

19 μm

25 μm

37 μm

44 μm

162 μm