CAMLOG&Science – Chapter 3

14 | 15

FATIGUE RESISTANCE AND SEAL: COMPARISON OF CAMLOG

®

AND OTHER IMPLANT SYSTEMS

Steinebrunner et al. (2005a, 2005b) tested the influence of long-term dynamic

loading on the fracture strengths of five different implant systems, one with

external connection (Brånemark) and four with internal connections

(FRIALIT

®

-2, Replace™Select, CAMLOG

®

and Screw-Vent

®

). The test specimens

were subjected to dynamic alternating loading for a maximum of 1.2 million

cycles at a rate of 1 Hz in a dual axis chewing simulator beforemaximum loading

was applied for fracture strength determination (Fig. 10). The results demon-

strated that theCAMLOG

®

and theReplace™Select implant systemswithdeep

internal tube-in-tube connections with cam-slot fixations had the highest

fracture strength score (Tab. 4 and Fig. 11).

A

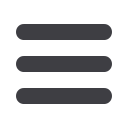

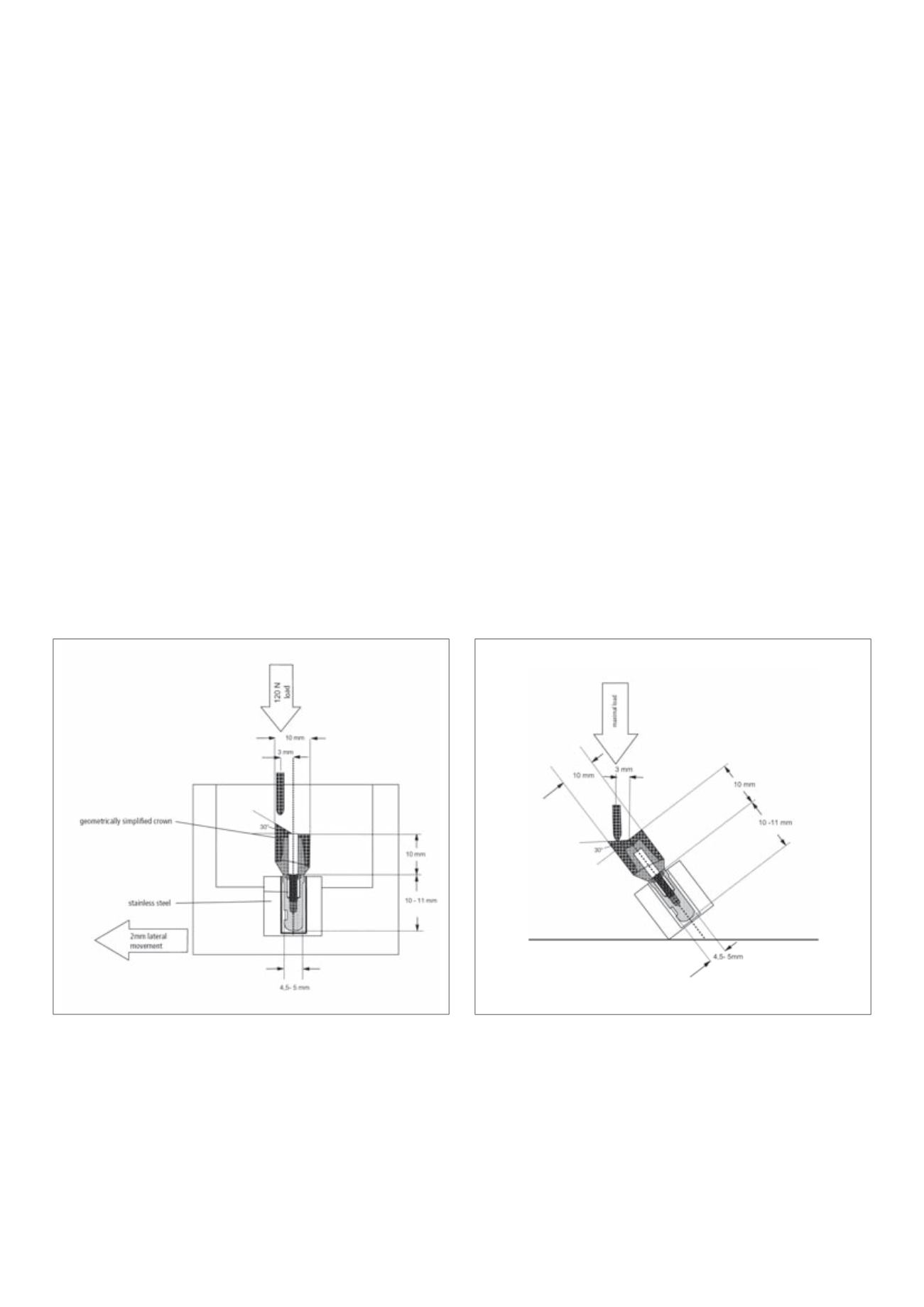

Fig. 10 A and B:

Schematic representation of the test set-up for (A) dynamic, alternating and

(B) maximum loading (adapted from Steinebrunner 2006). For each implant system to be tested,

16 implant-abutment combinations were fitted with a crown. A subgroup consisting of eight

samples was exposed to dynamic alternating load in a chewing simulator that took into account

a 30° cusp slope, a 2-mm lateral movement, and the physiological vertical chewing force of 120 N

B

reported by Richter (1995). The surviving implants of this subgroup as well as eight control samples

of the other subgroup were then subjected to the quasi-static fracture load test. Force input

point was identical to chewing simulation at 3 mm eccentric from the crown midpoint on the

central cusp, sloped at 30° to the occlusion plane and 11.5 mm distant from the implant shoulder

(Figure 10A).